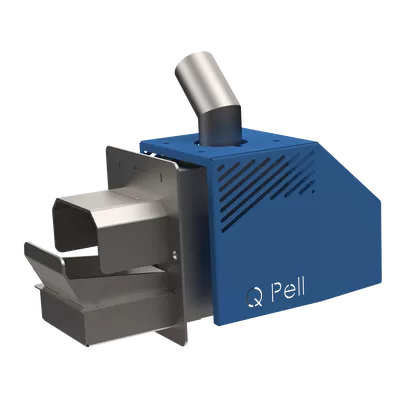

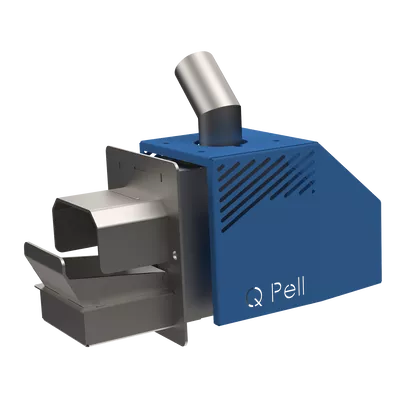

QPELL pellet burner for PELLPAL boilers with a capacity of 12, 18 kW

QPELL pellet burner for the 24 kW PELLPAL boiler

QPELL pellet burner with a power of 8 kW for the PELLPAL boiler

Fuel feeding system, pellet feeder for PELLPAL 12, 18, 24 kW boilers

Fuel feeding system - pellet feeder for PELLPAL 8 kW boiler

Steel or cast iron feeders are an essential component of ecological and economical central heating boilers. for pellets or for eco-pea coal. Choosing the right feeder will translate into economical and comfortable use of the boiler. The most common feeders in modern boilers are screw feeders.

The purpose of screw feeders is to deliver fuel (e.g. eco-pea coal or pellets) from the fuel tank directly to the furnace in the boiler. Thanks to the use of a screw feeder, the fuel is fed automatically, evenly and regularly, which significantly improves the comfort of the boiler operation.

Solid fuel feeders consist of several components, each of which plays an extremely important function.

A gear motor with an electric motor drives a screw (screw, auger) placed in the feeder pipe, which feeds solid fuel from the tank straight to the retort. The operation of the feeder, i.e. the transfer of fuel, is controlled by sensors on a programmable controller. Thanks to this, we can be sure that the right amount of fuel reaches the furnace in a given time. This saves time and does not require constant control of the amount of fuel transferred to the furnace. In the furnace chamber there are also a ring and a cast-iron ring, thanks to which the right amount of air is supplied to the place of combustion.

The combustion process is a complex process and, in addition to generating heat, other combustion products (gases, soot, vapors) are also produced, which should burn out in the combustion chamber. In order for the combustion process to run more ecologically and economically, a deflector is installed above the furnace, whose task is to break the flame in the boiler chamber so that it does not directly hit/hit the water jacket of the exchanger, burns fuel particles and maintains heat.

The combination of these components results in full use of fuel calorific value and comfortable, safe and economical use of the boiler with a feeder.