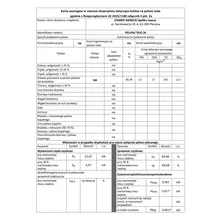

We present an ecological and efficient pellet boiler, model PELLPAL DUO with a power of 24 kW. This device is adapted to fuel such as wood pellets. The PELLPAL DUO boiler is characterized by very high efficiency, well-thought-out construction and excellent insulation of the device. All these parameters influence the high efficiency of the central heating boiler.

The PELLPAL DUO boiler with a power of 24 kW can easily produce the energy necessary to heat rooms with an area of up to 300 square meters and simultaneously heat domestic water. The fuel used in PELLPAL DUO boilers is wood pellets with a diameter of 6 to 8 mm. The fuel itself is very easy to store, does not produce dust, and at the same time, a minimal amount of ash remains after its combustion.

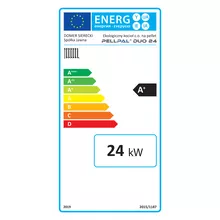

The efficiency of the PELLPAL DUO pellet boiler with a power of 24 kW exceeds over 90%, which is confirmed by tests carried out in accordance with the PN-EN 303-5:2021-09 standard, in which the heating device received class 5. Energy class of the central heating boiler is A+, which proves the energy efficiency and extraordinary efficiency of the equipment. This, combined with the low emission level of carbon monoxide, tar and dust (less than 20 mg/m3), makes it possible to benefit from higher funding for the replacement of the boiler in accordance with the EcoDesign eco-design.

Very high performance and efficiency of the device.

The equipment of the PELLPAL DUO pellet device with a power of 24 kW includes:

a steel and cast iron burner that burns pellets very efficiently,

a blower fan that supplies air to the combustion chamber,

PELLPAL DUO controller, which is responsible for igniting, maintaining and controlling the combustion process by regularly supplying fuel.

The additional equipment of the 24 kW pellet boiler is a controller equipped with a color and touch display (available as an equipment option in another configuration of the PELLPAL DUO 24 kW boiler), which will further facilitate the operation of the heating device. In the presented version, the boiler is equipped with a PELLPAL DUO controller. The boiler is designed to operate in an open system (system equipped with an overflow expansion vessel), in which the installation is directly connected to the air collected in the vessel. However, if there is a need to use it in a closed system, it will be necessary to purchase additional elements in the form of a cooling coil, DBV2 safety valve, SYR 5067 thermal protection and an expansion vessel. The devices used will eliminate the chance of overpressure, which may be dangerous for the installed installation.

Construction of the PELLPAL DUO pellet boiler with a power of 24 kW

The Pellpal Duo heating boiler with a capacity of 24 kW consists of a body made of certified boiler sheet metal with a thickness of 5 mm and a water jacket made of the same certified steel of the same thickness. The boiler is designed with horizontal channels in the upper part of the device. The boiler body has been designed so that the pellet burner can be mounted on the right or left side of the device. The boiler is equipped with a dedicated shutter that allows you to change the position of the feeder side in relation to the boiler body. As standard, it is delivered with a feeder and a tank mounted on the right side of the boiler.

A fuel and pellet tank is mounted directly above the feeder. It is made of 2 mm thick sheet metal. It has a seal installed under the tank cover to prevent moisture from entering the tank. The tank flap has a cover opening sensor installed. The fuel tank rests on a frame connecting its body with the body of the fuel feeder. A rubber gasket is mounted between them.

Fuel from the tank is poured directly into the screw feeder and transported in appropriate quantities to the burner located inside the combustion chamber. The PELLPAL DUO boiler has a protection in the form of the so-called firefighter, which prevents embers and fire from returning to the fuel chamber. There is a water tank installed at the back of the boiler, which is connected to a temperature sensor with a hose. If the sensor detects too high a temperature in the feeder, the water is drained and the burner is turned off in an emergency.

Control of the PELLPAL DUO boiler with a power of 24 kW The operation of the heating boiler is controlled by a microprocessor controller of the PELLPAL DUO boiler. It has initial settings for the device for pellet fuel. The controller menu has an option to change the fuel depending on the heating boiler in which the device is used. In the case of PELLPAL DUO boilers tested for burning pellets, they have initial settings for pellet fuel and settings adapted to the specified heating power of a specific boiler. The parameters were selected in such a way that the process of lighting and then burning and heating water in the central heating system was efficient and economical. The controller has a function of automatic ignition of pellets in the burner using an igniter (automatic heater) located in the combustion space.

Equipment of the PELLPAL DUO boiler with a power of 24 kW:

boiler body with insulation pellet tank PELLPAL DUO microprocessor controller pellet feeder and burner with automatic igniter combustion fan, DM 80 blower The documentation included with the boiler includes: operation and installation manual for the PELLPAL DUO pellet boiler PELLPAL DUO controller user manual boiler test certificate - an integral part of the boiler operating manual boiler test certificate - as above boiler declaration of conformity - as above boiler product card - as above ecodesign requirements card - as above boiler rating plate - placed on the heating device boiler energy label - as above

Example diagram of connecting the boiler to the central heating system. and domestic hot water with protection in an open system according to PN-91/B-02413

Description of the elements of an open system diagram

RP – overflow pipe RO – vent pipe

RS – signaling pipe RW – expansion pipe

RB – safety tube

NW – open expansion vessel

H >= 0.3 m – installation with a circulation pump on the feed

H >= 0.7 m – installation with a circulation pump on the return

Boiler protection scheme in a closed system with an external cooling coil (cooling vessel)

Description of the elements of the diagram of a closed system with an external coil

NS – cooling vessel ZB – safety valve

RZ – pipe with cold water inlet

RO – water outflow pipe

ZT – thermostatic valve

M + O + ZB – security group

M – manometer

O – air vent

ZB – safety valve

Diagram and description of the installation of equipment for protection in a closed system with a thermal protection valve type SYR 5067

Description of the elements of the diagram of a closed system with the DBV 2 valve

RZ – pipe with cold water inlet

RO – water outflow pipe

NP – diaphragmatic vessel

ZB – safety valve

ZZT – thermal safety valve. DBV 2

M + O + ZB – security group

M – manometer

O – air vent

Diagram and description of the installation of equipment for protection in a closed system with a thermostatic safety valve type DBV 2

Description of the elements of the diagram of a closed system with the DBV 2 valve

RZ – pipe with cold water inlet

RO – water outflow pipe

NP – diaphragmatic vessel

ZB – safety valve

ZZT – thermal safety valve. DBV 2

M + O + ZB – security group

M – manometer

O – air vent

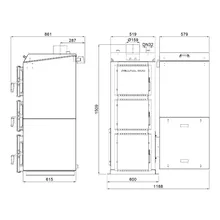

Dimensional drawing of the PELLPAL DUO pellet boiler with a power of 24 kW

Dimensions of the PELLPAL DUO pellet boiler with a power of 24 kW:

boiler body width: --- mm

width of the boiler body base: --- mm

set width: --- mm

boiler body depth: --- mm

depth of the boiler with burner: --- mm

boiler body height: ---- mm

height to the lower edge of the flue: --- mm

height of the boiler and tank set: ---- mm

conduit diameter: --- mm

installation water connections: DN --- cal

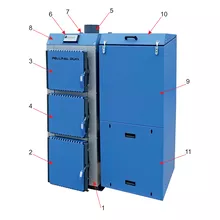

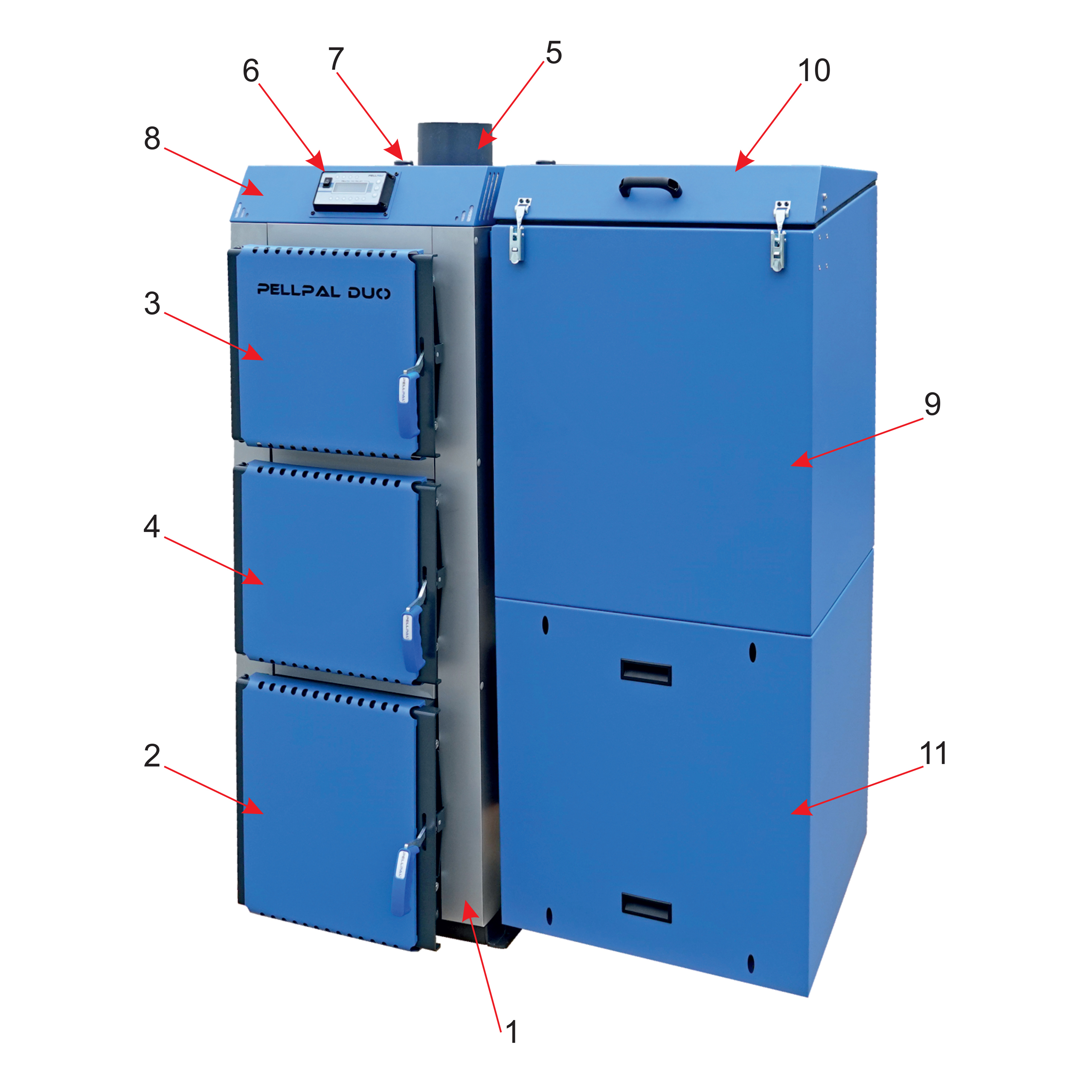

List of components of the PELLPAL DUO boiler with a power of 24 kW

1 – body with thermal insulation

2 – fireplace and ash-pan doors

3 - upper cleaning door

4 - lower cleaning door

5 – flue

6 - controller

7 - power supply connector

8 - insulation cover

9 – fuel tank

10 - tank cover

11 - burner and feeder housing

The warranty for the PELLPAL DUO boiler is 60 months and counts from the date of issue and purchase of the boiler. The boiler warranty is granted provided that all requirements specified in the user manual (see appendices) are met.

Attention! Failure of the user to read and comply with the requirements specified in the user manual, attempt to repair it on his own, interference with the structure of the boiler and accessories, and other reasons not resulting from the manufacturer's fault will void the warranty.

The warranty also covers equipment mounted to the boiler (fan, controller), but for the period and under the conditions specified in the warranty card of the manufacturer of this equipment.

The warranty does not cover:

mechanical damage occurring during transport, assembly and operation of the boiler

elements that wear out during the operation of the boiler (sealing cord, seals, swirlers, hinges, screws, nuts, screw safety pin, handles and hooks, ceramic elements, flame deflector, paint coatings). The warranty does not cover the act of replacing them

events described in "Causes of disturbances and failures in boiler operation"

no confirmation of boiler installation and protection according to PN-91/B-02413 or PN-EN 12828:2003

activities to be performed by the user specified in the user manual

corrosion, pitting and loss of boiler material caused by improper operation of the boiler (maintaining the minimum return temperature in the boiler - temperature protection)

damage and its effects caused by the failure to use chimney flues that do not comply with the requirements that take into account the likelihood of flue gas condensation and are resistant to harmful chemical compounds, including acids.

damage due to exceeding the maximum temperature and pressure values in the boiler

AVAILABLE NOW

AVAILABLE NOW

Payment in cash, Payment via bank transfer, Online Payments Payment Cards, ApplePay, Google Pay - P24, PayPro SA, Payment by bank transfer - wait for the proforma invoice to be sent

Fast Blik payments.