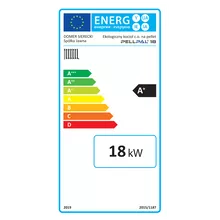

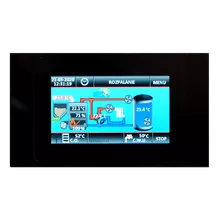

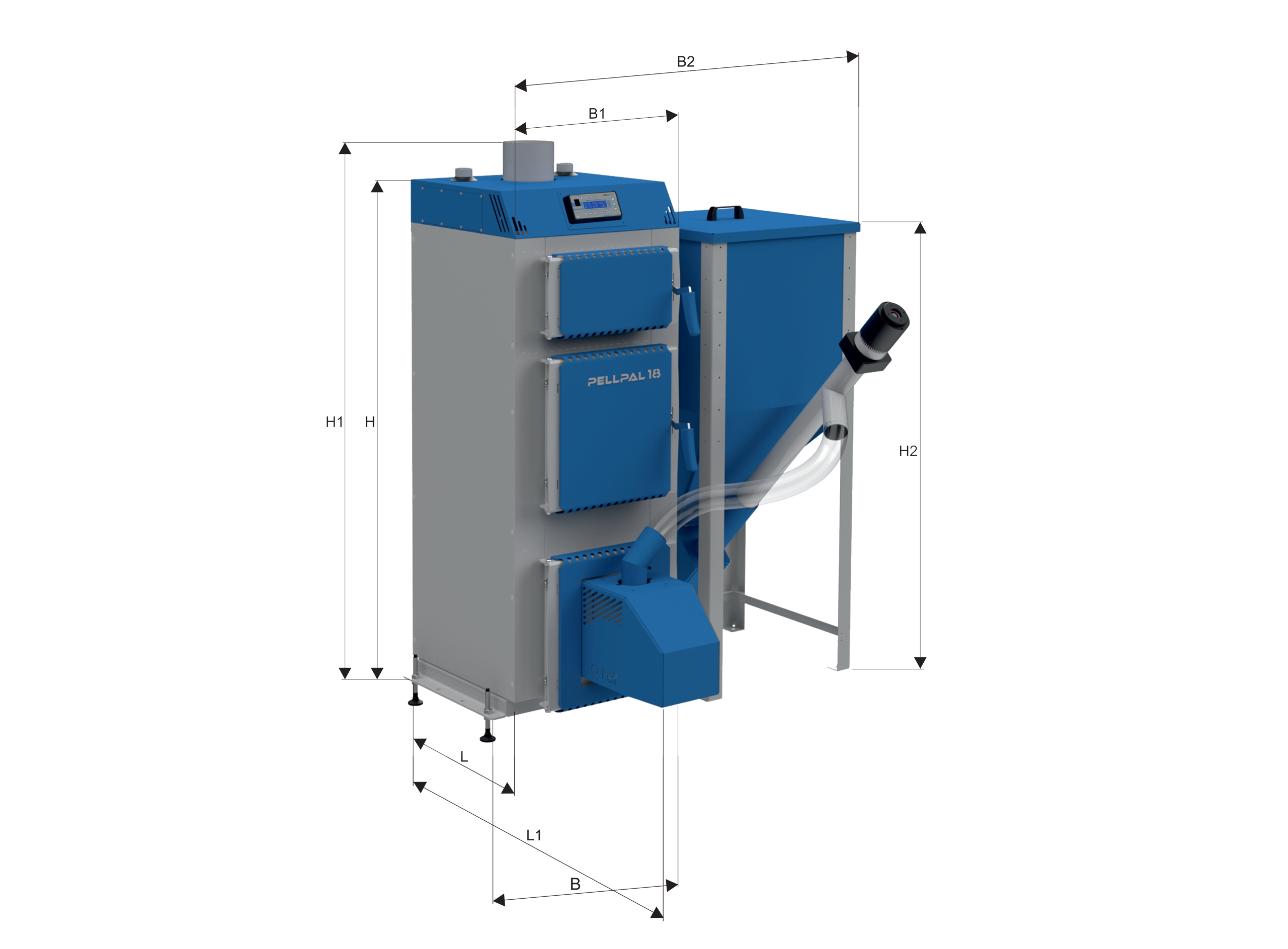

PELLPAL pellet boiler with a power of 18 kW LCD touch controller - 5 EcoDesign class

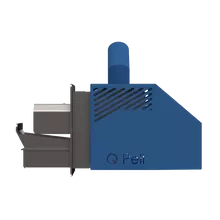

We present to you a modern and economical biofuel heating device. The 18 kW pellet boiler is characterized by high efficiency, thanks to which the device is able to insulate rooms with an area of up to 220 m2, while heating utility water at the same time. The mentioned biofuel is pellet with a diameter of 6 to 8 mm, which perfectly meets the requirements of larger single-family houses and public utility buildings.

The efficiency of the 18 kW pellet boiler reaches 91.5%, which is confirmed by tests carried out in accordance with the EN 303-5 standard, in which the heating device received the 5th class. Central heating boiler energy class is A+, which certifies the energy efficiency and extraordinary efficiency of the equipment. And this, combined with the low level of emissivity of carbon monoxide, tar and dust (lower than 20 mg/m3), gives you the opportunity to take advantage of higher funding for boiler replacement in accordance with the EcoDesign ecodesign.

- Add feedback:

- Code: 14541

- Manufacturer: PELLPAL

- Manufacturer's code: 5902429315473

- Weight: 255 kg

-

Availability:

TEMPORARILY NO

TEMPORARILY NO

- Net Price: €2,763.03 €3,398.53

- pcs.

-

Payment in cash, Payment via bank transfer, Online Payments Payment Cards, ApplePay, Google Pay - P24, PayPro SA, Payment by bank transfer - wait for the proforma invoice to be sent

-

Fast Blik payments.

Zobacz inne wersje

We complete the order within 24 hours.

The product is covered by a one-year warranty.

You can return the product within 14 days.

Parametry techniczne kotła PELLPAL moc 18 kW

| Linia kotłów: | PELLPAL |

| Stosowany opał: | pellet |

| Znamionowa moc cieplna [kW]: | 18 |

| Minimalna moc cieplna [kW]: | 5,31 |

| Klasa kotła: | 5, EcoDesign |

| Klasa energetyczna: | A+ |

| Emisja pyłów PM [mg/m3]: | 18,5 |

| Umieszczony na liście ZUM: | TAK |

| Dofinansowanie: | Kocioł podlega dofinansowaniu, podwyższony standard |

| Sprawność cieplna [%]: | 91,5 |

| Powierzchnia ogrzewanego pomieszczenia [m2]: | do 220 |

| Pojemność wodna [l]: | 80 |

| Masa kotła [kg]: | 255 |

| Zużycie paliwa - max [kg/h]: | 4,0 |

| Ciąg kominowy [mbar]: | 0,2 |

| Znamionowa temperatura spalin [OC]: | 92 |

| Znamionowa ilość spalin [kg/s]: | 0,0099 |

| Minimalna temperatura spalin [OC]: | 89 |

| Minimalna ilość spalin [kg/s]: | 0,0058 |

| Pojemność zasobnika paliwa [kg]: | 115 |

| Ciśnienie próby wody [bar]: | 4 |

| Ciśnienie robocze [bar]: | 2 |

| Max. temperatura robocza [OC]: | 85 |

| Min. temperatura powrotu [OC]: | 55 |

| Zakres regulacji temperatury [OC]: | 50 - 80 |

| Min. temperatura wody kotłowej [OC]: | 10 |

| Opory przepływu wody ΔT=20 [mbar]: | 2 |

| Opory przepływu wody ΔT=10 [mbar]: | 8 |

| Przekrój czopucha: | okrągły |

| Średnica czopucha [mm]: | 130 |

| Średnica króćców wodnych: | DN 25 |

| Zasilanie elektryczne 230 V / 50 Hz [A/W]: | 1,9 / 350 |

| Pobór mocy elektrycznej (100% mocy) [W]: | 350 |

| Pobór mocy elektrycznej (30% mocy) [W]: | 15 |

| Pobór mocy elektrycznej (czuwanie) [W]: | 3 |