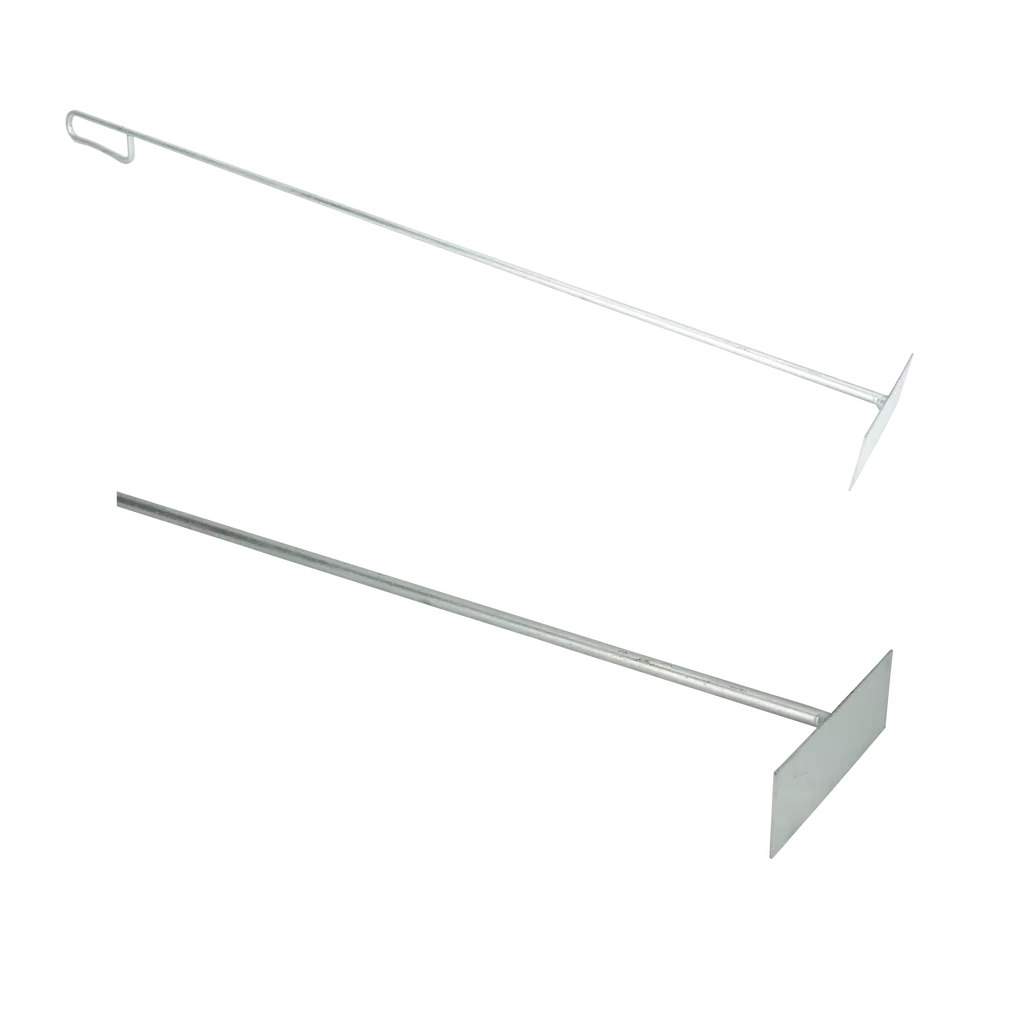

Scraper for cleaning the grate boiler, length 80 cm

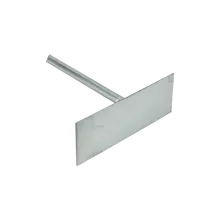

A metal scraper is used to clean the hearth in central heating boilers. It is a tool in the form of a rod, and at its end there is a crossbar. It helps to thoroughly clean the inside of the boiler. The total length is 80 cm. In most heating boilers, it is enough to reach the end of the flue and difficult places inside the boiler.

- Add feedback:

- Code: 5842

- Manufacturer: DOMER

- Manufacturer's code: 5902429311024

- Weight: 1 kg

-

Availability:

AVAILABLE NOW

AVAILABLE NOW

- Net Price: €1.42 €1.75

- pcs.

-

Payment in cash, Payment via bank transfer, Online Payments Payment Cards, ApplePay, Google Pay - P24, PayPro SA, Payment by bank transfer - wait for the proforma invoice to be sent

-

Fast Blik payments.

The product is shipped within 24 hours.

We complete the order within 24 hours.

You can return the product within 14 days.

A metal scraper is used to clean the hearth in central heating boilers. It is a tool in the form of a rod, and at its end there is a crossbar. It helps to thoroughly clean the inside of the boiler. The total length is 80 cm. In most heating boilers, it is enough to reach the end of the flue and difficult places inside the boiler.

Technical parameters:

Length: 80 cm

material: steel

Why clean a central heating boiler?

In order to save fuel and achieve the declared power and thermal efficiency of the boiler, it is necessary to keep the combustion chamber and convection ducts clean. While the use of our central heating installation is carried out in the right way, we cannot stop the heat source from getting dirty inside the boiler. The burning of solid fuels causes the deposition of soot and ash on the walls of flue gas ducts. This, in turn, causes a reduction in the boiler's heat output and an increase in fuel consumption. This is caused by reduced chimney draft and acceleration of fuel combustion. So, in order to prevent the deterioration of the thermal properties of our boiler, we should not forget about its frequent cleaning.

In the furnace chamber of the boiler, special attention should be paid to periodic cleaning of micro-gaps in the automatic furnace plate.

Convection ducts in which fly ashes settle should be cleaned systematically, every 3÷7 days, and in particular when the boiler is used in the "traditional furnace" mode. A significant issue is the frequency of cleaning the central heating boiler. appropriate type of wood, it should be enough to clean it once every few weeks, while when we burn coke, we should do it much more often - once every 7 to 10 days, and once every few years, the boiler should be cleaned of the so-called scale. precipitate (e.g. aqueous hydrochloric acid).

The tools that the boiler is equipped with are used for cleaning. Cleaning of the convection ducts of the boiler is possible thanks to the front cleaning door and the furnace door. In addition, the air chamber located in the rear part of the boiler, where dust falling from the automatic furnace plate is collected, should be periodically cleaned. Such cleaning is carried out through the side cleaning hole.

We use wire brushes or pokers to tidy up solid fuel boilers. Large boilers can be cleaned with compressed air. Cleaning is carried out through the cleaning openings of the boiler, remembering that the flue gas damper in the flue is open. The boilers may have a rich number of these openings and they may be located in various ways (top, side or back). The remaining ash is cleaned through the cleaning hole in the lower part of the boiler with the help of a scraper. After completing the work, we must remember to hermetically close all cleaning openings.

Cleaning the chimney duct is also important for the correct operation of the boiler.

After the end of the heating season or in other cases of planned shutdown of the boiler, the fuel portion should be burnt out. After the boiler has been extinguished and cooled down, remove all remains of burnt fuel from the furnace and clean and maintain the entire boiler. It is necessary to maintain (by lubricating with oil) the internal partitions of the combustion chamber and all movable elements. For the period when the boiler is not in operation, the mechanism feeding fuel to the furnace chamber should be protected in particular by lubricating the horizontal guides.

Informacje o bezpieczeństwie produktu

Informacje o producencie