The latest regulations and anti-smog requirements contain very high recommendations regarding the efficiency and effectiveness of heating furnaces. The presented PellPal D boiler with a power of 20 kW for wood is a model that easily heats utility water and ensures a comfortable temperature of rooms located on an area of 160 to 200 m². The fuel is wood in the form of logs, which are placed in a specially designed charging chamber before the machine starts working. Its construction allows for a significant reduction in the intensity of refuelling.

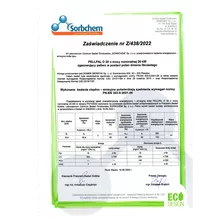

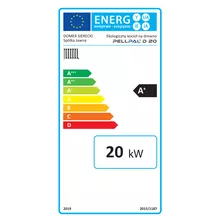

In addition, the 20 kW PellPal D wood boiler is also characterized by a high level of efficiency, which reaches 90.9%. In control tests in accordance with the EN-303-5 standard, the furnace gained class 5 at full and declared minimum efficiency. The energy efficiency rating obtained by the device is A+, which, together with the low level of PM emissivity (below 20 mg/m3), ensures compliance with the EU EcoDesign assumptions.

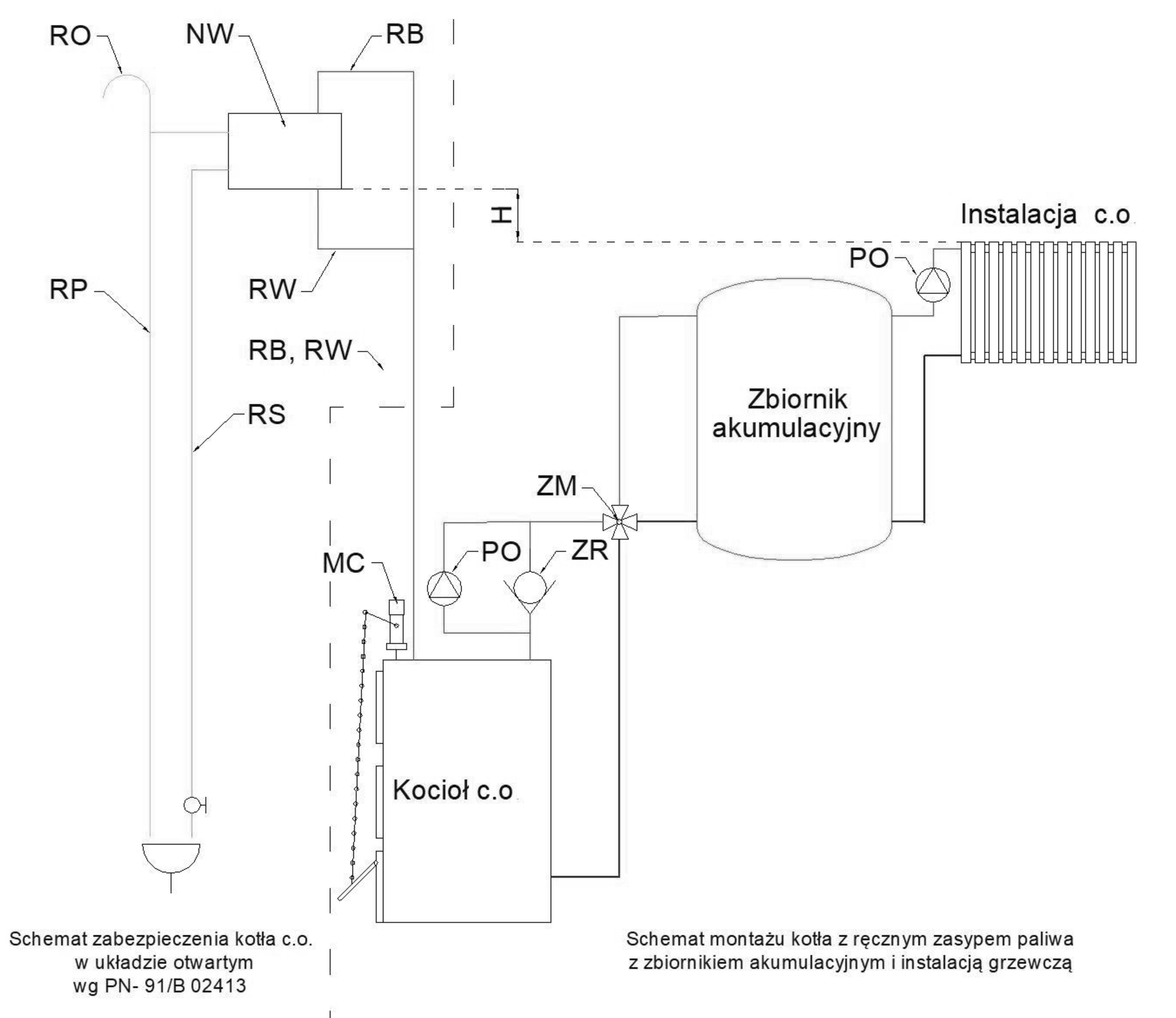

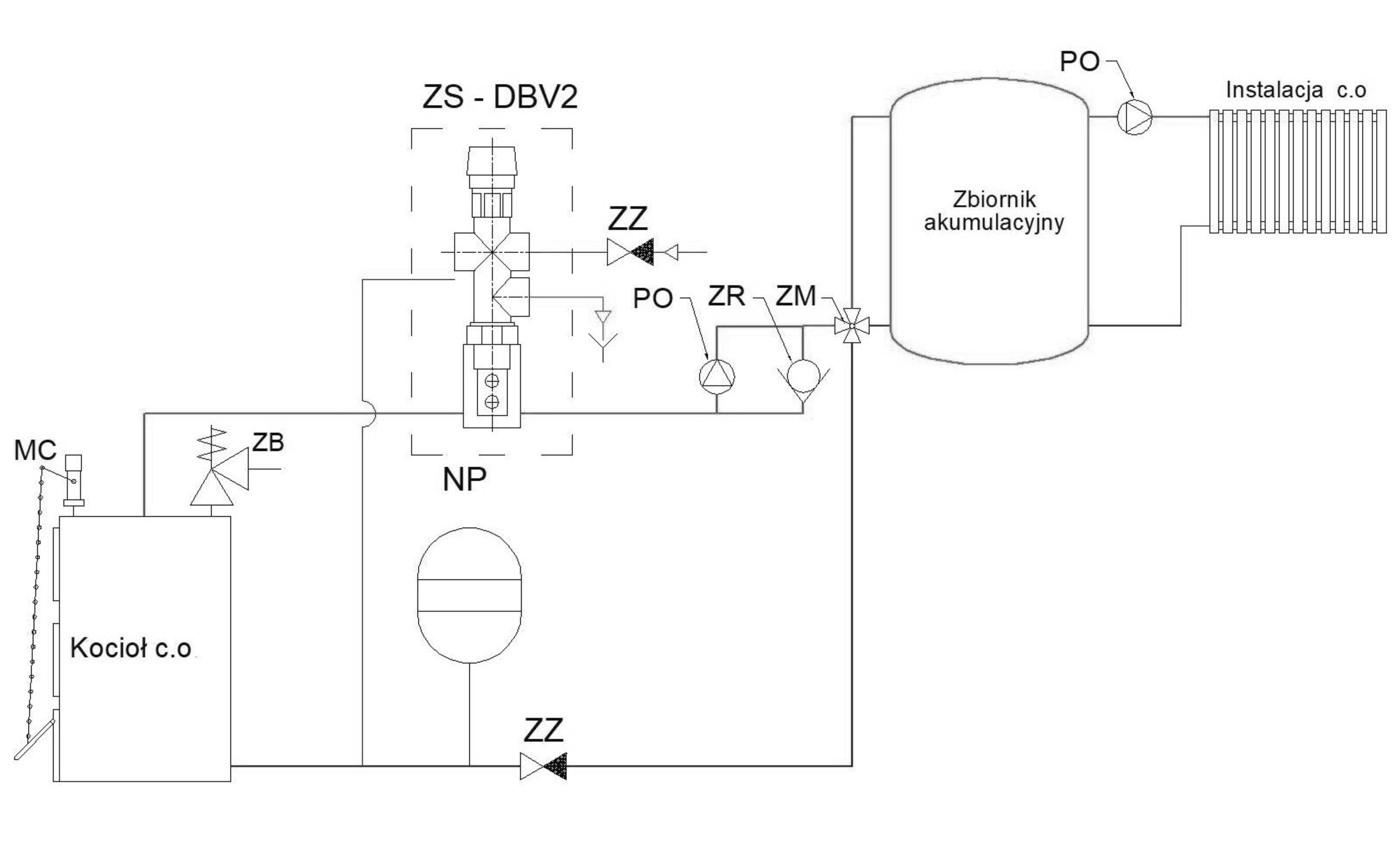

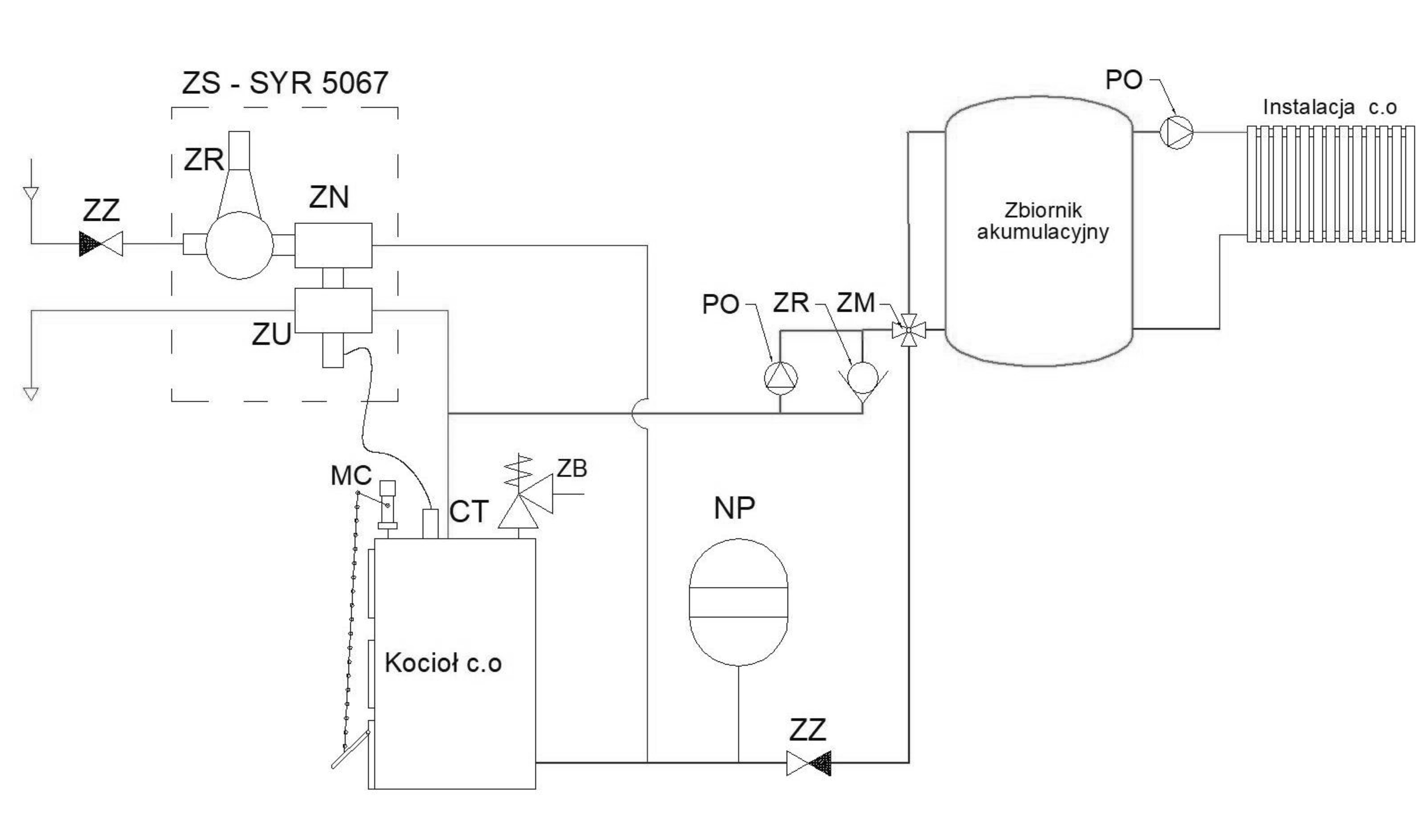

In addition, the presented 20 kW PellPal D wood boiler is also distinguished by its versatility, which, depending on the user's preferences, allows the device to operate in two systems: open and closed.

The first requires only the use of an open expansion vessel. In turn, for the second one, it is mandatory to purchase external elements - a cooling coil, an expansion vessel, a DBV-2 valve responsible for dissipating excess heat power, as well as a SYR-5067 thermal protection valve, which is used in models without a cooling exchanger. For both open and closed systems, an accumulation tank with a minimum capacity of 840 liters must be used.

In accordance with the eco-design requirements (Commission Regulation (EU) 2015/1189), boilers with manual fuel charging should be operated with a water heat accumulator, an accumulation tank with a capacity depending on the heat output. The required capacity of the accumulation tank was determined in accordance with the requirements of the EN 303-5 standard and the Regulation of the EU Parliament 2015/1189. According to the above-mentioned requirements, the capacity of the accumulation tank cannot be lower than that indicated in the technical data of the PellPal D boiler.

The simple design of the 20 kW PellPal D boiler guarantees failure-free operation, significant ease of maintenance and the need to refuel. Before installing the device, we encourage you to read the documentation and instructions attached to the purchase.

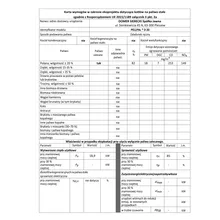

Basic technical data of the PELLPAL D 20 kW boiler

rated thermal power: 20 kW

area of heated rooms: from 160 to 200 m2

thermal efficiency: 90.9%

energy class: A+

working pressure: 2 bar

boiler water capacity: 83 liters

maximum operating temperature: 95 OC

chimney draft: 0.27 mbar

fuel loading weight: 10.5 kg

length of logs (wood logs): 240 - 260 mm

diameter of logs (wood logs): FI 30 - 120 mm

boiler weight: 350 kg

accumulation tank capacity: 840 liters

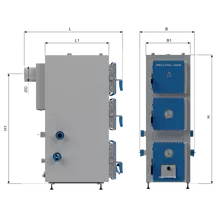

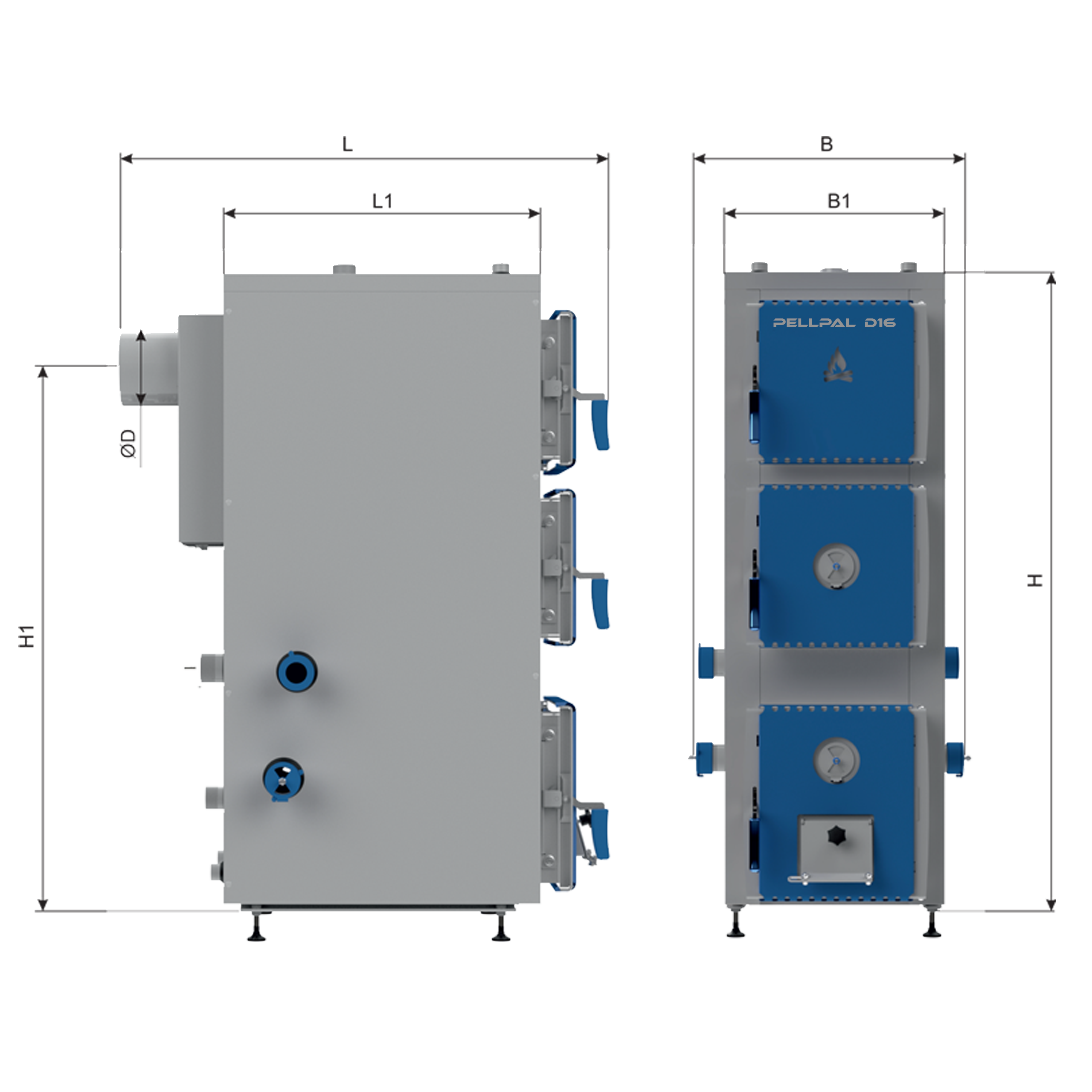

Construction of the PELLPAL D wood boiler with a power of 20 kW

The boiler body and outer jackets are made of certified boiler sheet P265GH with a thickness of 5 mm. Individual elements of the boiler are laser cut, which ensures maximum accuracy and 100% repeatability of individual elements that make up a given heating device.

The structure is based on an exchanger with horizontal convection channels located in the upper part of the furnace chamber. In the lower part of the boiler there is a furnace equipped with a cast iron grate consisting of cast iron beams arranged next to each other.

The boiler is equipped with tightly closed doors that enable boiler operation, fuel loading, cleaning of convection channels and combustion chamber. A flap has been designed in the lower door, the position of which is regulated by the Regulus air draft regulator. The chimney outlet (flue) is located at the back of the boiler. Connection pipes for connecting the boiler to the heating system are located on the top of the boiler and in its rear part. At the top of the boiler there are also stub pipes for mounting the draft regulator controlling the operation of the air inlet flap.

The warranty for the boiler is 24 months and counts from the date of its issue, i.e. the purchase of the boiler. The warranty for the boiler is provided provided that all the requirements specified in the instruction manual are met (see attachments). Attention! User's failure to read and comply with the requirements specified in the operating manual, attempt to repair it on their own, interfere with the construction of the boiler and axles

equipment, and for other reasons not resulting from the manufacturer's fault, voids the warranty.

The warranty also covers the accessories mounted to the boiler (fan, controller - if any), but for the period and under the conditions specified in the warranty card of the manufacturer of these accessories.

The warranty does not cover:

mechanical damage caused during transport, assembly and operation of the boiler

consumable parts during boiler operation (sealing cord, seals, turbulators, hinges, screws, nuts, handles and catches, ceramic elements, paint coatings). The warranty also does not cover the act of replacing them

events described in "Causes of disturbances and malfunctions in boiler operation"

no confirmation of the boiler installation and protection according to PN-91/B-02413 or PN-EN 12828:2003

the actions to be performed by the user specified in the user manual

corrosion, pitting and loss of boiler material caused by improper operation of the boiler (maintaining the minimum return temperature in the boiler - temperature protection)

damages and their effects caused by the failure to use flues that are inconsistent with the requirements taking into account the likelihood of flue gas condensation and resistant to harmful chemical compounds, including acids.

damage as a result of exceeding the maximum values of temperature and pressure in the boiler

AVAILABLE NOW

AVAILABLE NOW

Payment in cash, Payment via bank transfer, Online Payments Payment Cards, ApplePay, Google Pay - P24, PayPro SA, Payment by bank transfer - wait for the proforma invoice to be sent

Fast Blik payments.